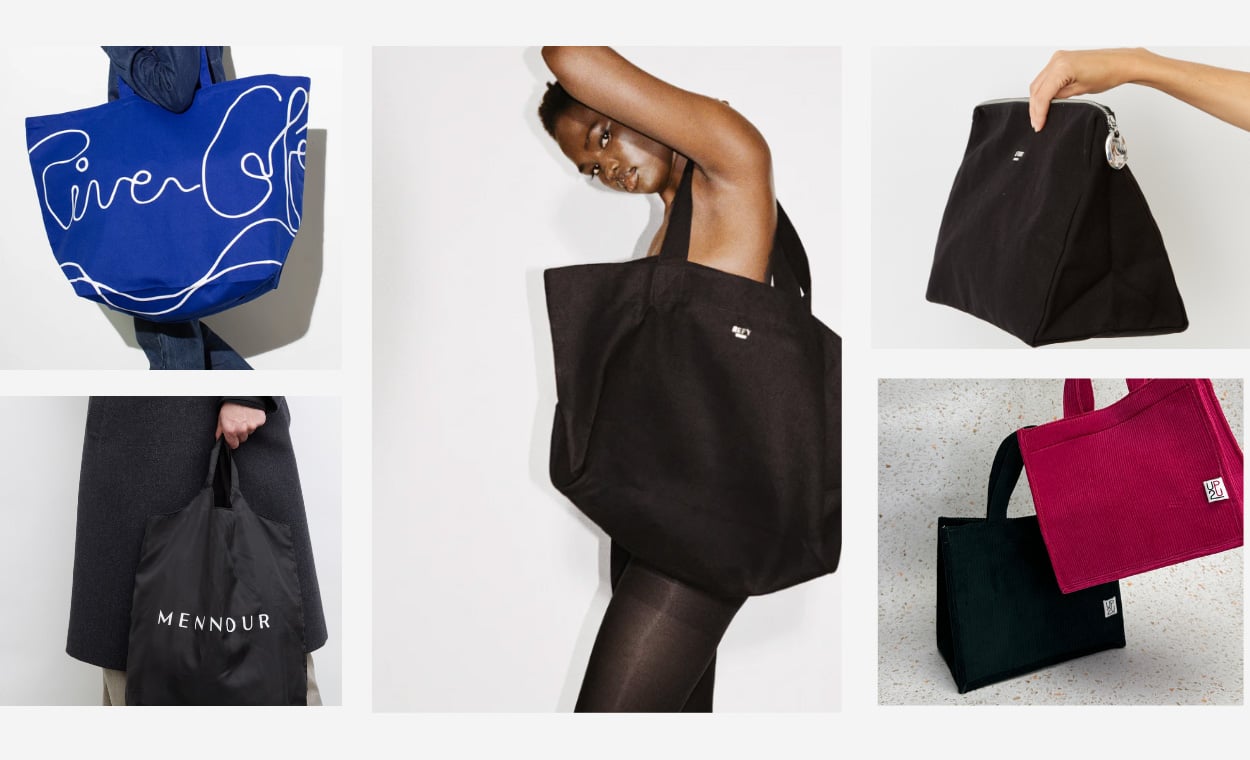

Colour is a catalyst in sales success within the fashion industry. The first thing consumers notice about a piece of clothing before the fabric or size is the colour of the garment. The brightness or shade of clothing as well as how it might suit their complexion and their personal preferences. However, colour dyes in clothing is known to be harmful to the environment and the people in the surrounding areas close to factories.

Due to the increasing usage of ink and dyes within the production process in garment factories, there is a high level of ink-like water flowing through rivers. This usually includes a toxic mixture of chemicals that are being discarded by the fashion industry’s synthetic dye processes. Up to 200 tonnes of water are used per tonne of fabric in the textile industry. According to authors and researchers Michael Braungart and William McDonough’s book Cradle to Cradle they states that, on average, only 5% of the raw materials involved in the production and delivery processes is contained within a garment. Meaning that we also don’t see the 95% of the material process, most of which is hidden water.

In countries such as Bangladesh, China and India, their water systems have become contaminated due to the postproduction water containing residual dye, mordants, chemicals and micro-fibers are released into the pipes untreated. As the water is released, there is not any way to trace the chemical water back to the sources, therefore factories can do so anonymously.

In China, over 70% of the rivers are polluted meaning citizens cannot use the water from wells to use for domestic purposes such as drinking water or to use for personal hygiene.

Water Based: What Is It? What Is The Difference

You might be wondering what the difference between water-based inks and other inks and dyes such as Azo dyes or plastisol ink. The difference and main reason companies may opt to use inks such as these are cost regardless of their impact on the environment.

However, water-based inks are known to be the green version of inks such as plastisol because it does not contain any of the toxic chemicals (PVC or Phthalates).

What Is Reach Compliant?

All Supreme Creations ink is REACH compliant, but what does it mean? is a testing document certifying that the product used in the factory is compliant with the EU REACH regulation (EC) No 1907/2006.

Why Choosing Supreme Creation As Your Ethical Textile Manufacturer?

At Supreme Creations, we want to ensure our customers that all our production processes and inks have been observed and used in a safe and ethical manner. Meaning that the bags that you order will be ethically made with water-based inks including REACH compliant inks that are safer for the environment.

Inks And Dyes In The Textile Industry: The Real Impact On Environement

France

France

Germany

Germany

Italy

Italy

Spain

Spain

United States

United States

India

India